Unbalanced machines waste time, money and resources.

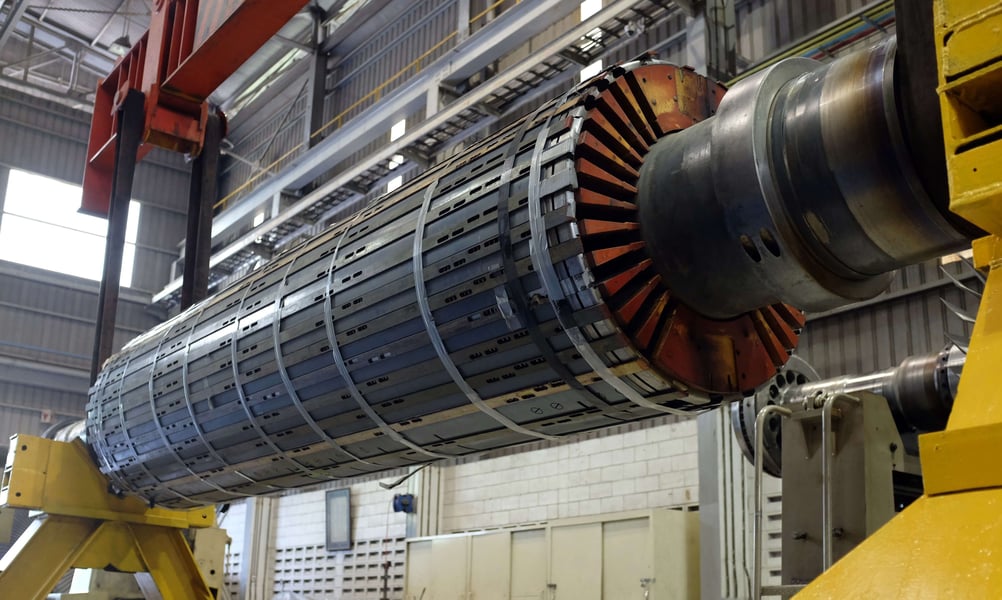

Dynamic balancing is used to fix uneven or ‘unbalanced’ rotating components of a machine such as fans, turbines, rolls, spindles, etc. When parts become unbalanced, it can cause a machine to make noise, start to vibrate and even prematurely fail. Properly balancing rotating equipment extends machine component life, smoother and quieter running equipment, reduces operation downtime and overall cost. Kirby Risk technicians have the expertise and knowledge to balance your machinery at any location – your facility or on the job site.